In the world of industrial air compression, the debate between the traditional Roots blower and the more modern screw blower has garnered significant attention. As industries look for more efficient, reliable, and cost-effective solutions for air-moving applications, the screw blower is rapidly gaining favor over its Roots counterpart.

Historically, Roots blowers have been a staple in a variety of industries, providing high-capacity air movement with relatively simple mechanical design. They work by using two rotors to trap and move air, making them ideal for applications that require a steady, high volume of air at relatively low pressures. However, as industrial demands evolve, so too must the technologies that serve them.

Why Screw Blowers Are Gaining Popularity

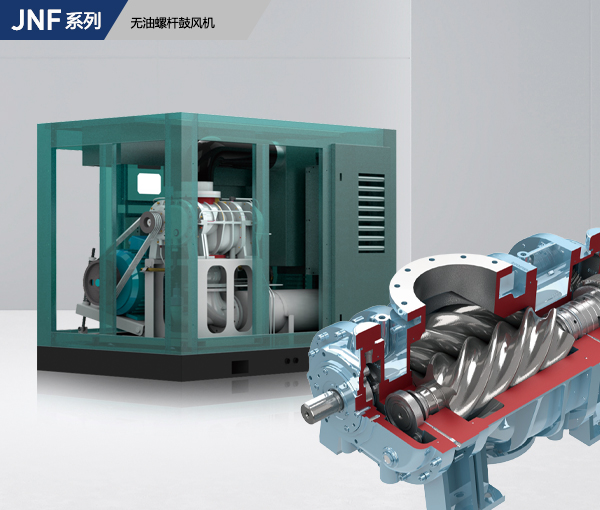

The screw blower, an innovation of the traditional positive displacement blower, is engineered with a pair of interlocking helical rotors. This design allows the blower to move air with greater efficiency and reduced energy consumption, a critical factor in today’s energy-conscious industries. Compared to Roots blowers, screw blowers tend to operate at lower noise levels and with better reliability, making them a preferred choice for many modern facilities.

One of the key advantages of screw blowers is their ability to deliver a more consistent airflow at a higher pressure and with lower pulsation. This leads to smoother operations in applications such as wastewater treatment, pneumatic conveying, and industrial air supply, where air flow consistency is crucial. Screw blowers also tend to have a longer lifespan due to their lower operating temperatures and reduced mechanical wear, offering companies a more durable solution with less frequent maintenance.

Energy Efficiency: A Significant Factor

The efficiency of screw blowers has been a major factor in their rise. These blowers typically consume less energy compared to Roots blowers, which often struggle with high energy consumption at higher pressures. This translates to significant savings for businesses in energy costs, a critical consideration in industries with heavy operational demands. Screw blowers are designed with variable speed drives (VSD) that allow them to adjust their performance according to the demand, leading to even greater energy savings during periods of lower air requirements.

Noise Reduction: A Modern Solution for Modern Facilities

Another area where screw blowers outshine Roots blowers is noise reduction. Roots blowers, due to their high-speed rotor motion, can be noisy, creating a disruptive working environment. Screw blowers, by contrast, are known for their quieter operation. This feature is especially important in facilities where noise pollution must be minimized for the comfort and safety of workers, as well as to comply with environmental noise regulations.

Cost of Ownership: A Long-Term Investment

While the initial investment for screw blowers may be higher than that of Roots blowers, the total cost of ownership is often lower in the long term. With lower maintenance requirements, reduced energy consumption, and increased reliability, screw blowers are proving to be a sound investment for companies looking to improve their operations. Their ability to run efficiently for extended periods, coupled with their longer operational life, helps businesses reduce costs over time and enhance overall productivity.

A Shift Towards the Future

As industries continue to prioritize sustainability, energy efficiency, and cost-effectiveness, screw blowers are increasingly seen as the future of air-moving technologies. Their superior efficiency, lower noise levels, and longer lifespan make them a highly attractive option for a wide range of applications. In contrast, Roots blowers, with their higher energy usage and maintenance requirements, are gradually being outpaced by this newer, more advanced technology.

In conclusion, the screw blower has emerged as a superior choice for many industrial applications, offering distinct advantages over the traditional Roots blower. With its energy efficiency, reduced noise, and long-term reliability, the screw blower is setting the standard for air-moving solutions in the modern industrial landscape.

Post time: Jan-24-2025