“Innovation, not imitation, has created world champion companies. Only innovation and continuous improvement can stand at the top.” In the past decade, Kaishan Group has been focusing on research and development, relying on innovation to move towards the top of the compressor industry. Among them, Guangdong Ganey Precision Machinery Co., Ltd. (hereinafter referred to as “Ganey Precision”), an important member company of the group, has innovated and developed a large number of oil-free compressor products with independent intellectual property rights in accordance with the group’s strategic planning, and is striving to become the “hidden champion” of the domestic oil-free compressor industry.

Dry oil-free screw air compressors, water-lubricated oil-free single screw air compressors, oil-free vortex air compressors, Ganey Precision’s oil-free air compressor product spectrum is complete. The 200kW\250kW water-cooled permanent magnet two-stage compression oil-free water-sprayed single screw air compressor launched this time has been confirmed by the test report provided by the most authoritative testing agency in China, and the energy efficiency has even reached the first-level energy efficiency national standard value of the same power of oil-sprayed screw air compressors. This is the most brilliant highlight of this innovative product.

As one of the brands under Kaishan Group, Ganey Precision mainly focuses on the research and development and manufacturing of oil-free air compressors and medium-pressure compressors. Since the first oil-free water-lubricated compressor was launched in 2008, it has been nearly 20 years. The company has continued to develop in the field of water-sprayed single-screw compressor products. Whether it is research and development, manufacturing, or market application, the products have been fully improved, with stable and reliable quality, and are deeply favored by customers.

Adhering to the concept of technology-driven future, constantly improving the comprehensiveness of product spectrum and enhancing the depth of product competitiveness, another masterpiece launched in 2024-40 cubic series two-stage water-sprayed single-screw air compressor, which is more efficient, more energy-saving, and more environmentally friendly, and is more in line with the needs of market and social sustainable development.

A water-sprayed single-screw air compressor refers to a single-screw air compressor that sprays water medium into the compression chamber to participate in compression. During the air compression process, there is no contact or participation of lubricating oil throughout the process, no gearbox, no oil tank, no oil cooler, etc., to achieve an oil-free compressor and obtain oil-free compressed air. Execute the industry standard JB/T 11882-2014 “General Water-Injected Single-Screw Air Compressor”, and Ganey Precision participates in the preparation of this standard.

Product Highlights

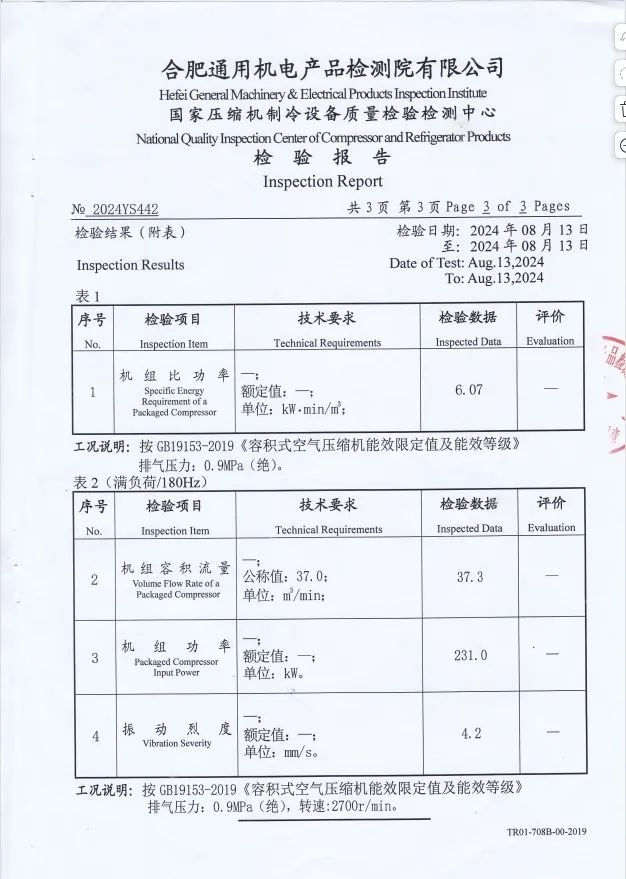

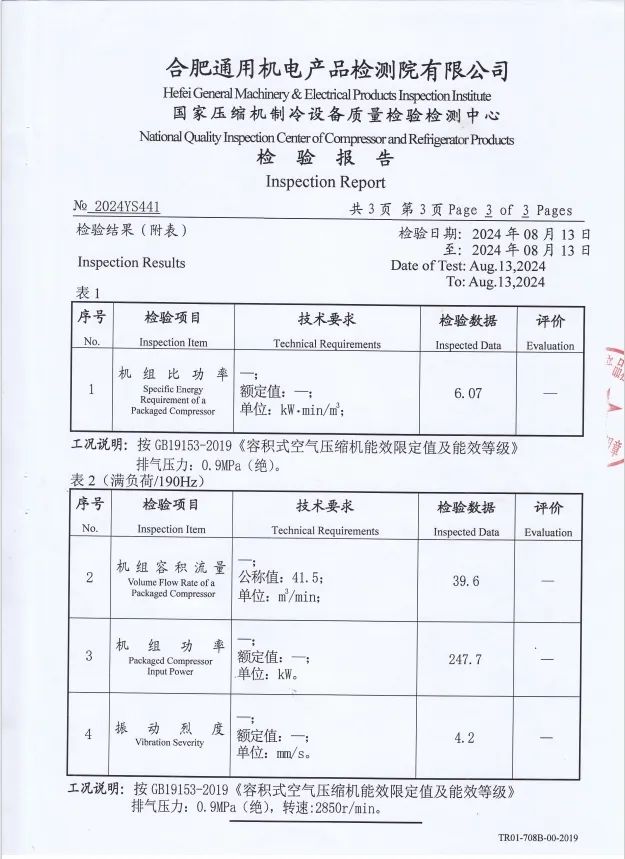

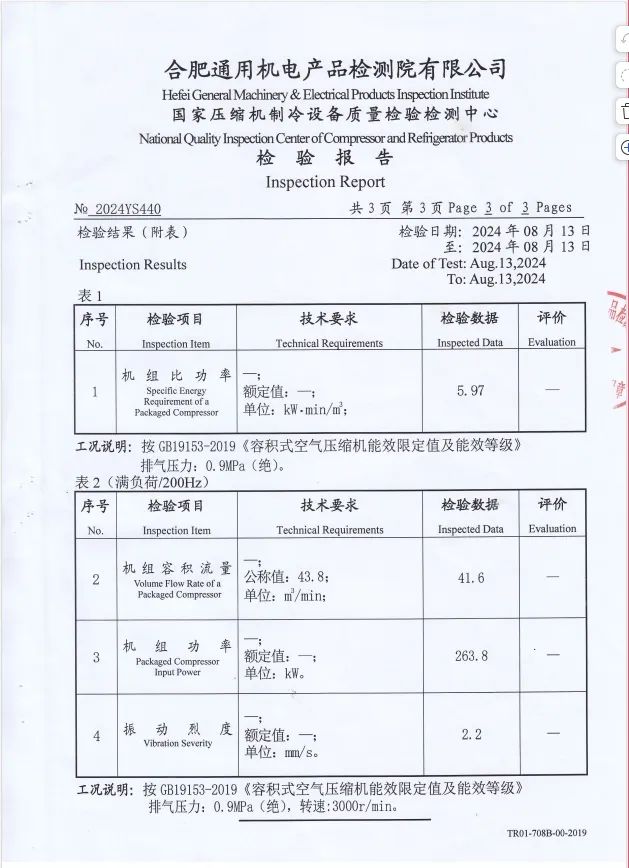

1. The core highlight of the two-stage water-injected single-screw air compressor is that it is more efficient, energy-saving and environmentally friendly than single-stage compressors. The 40 cubic series two-stage water-injected single-screw air compressors are tested by industry-recognized authoritative testing agencies for 200, 220, and 250kW water-cooled permanent magnet variable frequency units. The report is shown in the figure below. The unit input power ratios are 6.07, 6.07, and 5.97kW/(m³/min) respectively. The input power ratios of 200 and 250kW units are equivalent to the first-level energy efficiency value of the same-level power of the variable speed oil-injected rotary compressor in the “Energy Efficiency Limit Values and Energy Efficiency Grades of Volumetric Air Compressors” (GB 19153-2019), which is an energy-saving star product for oil-free volumetric compressors.

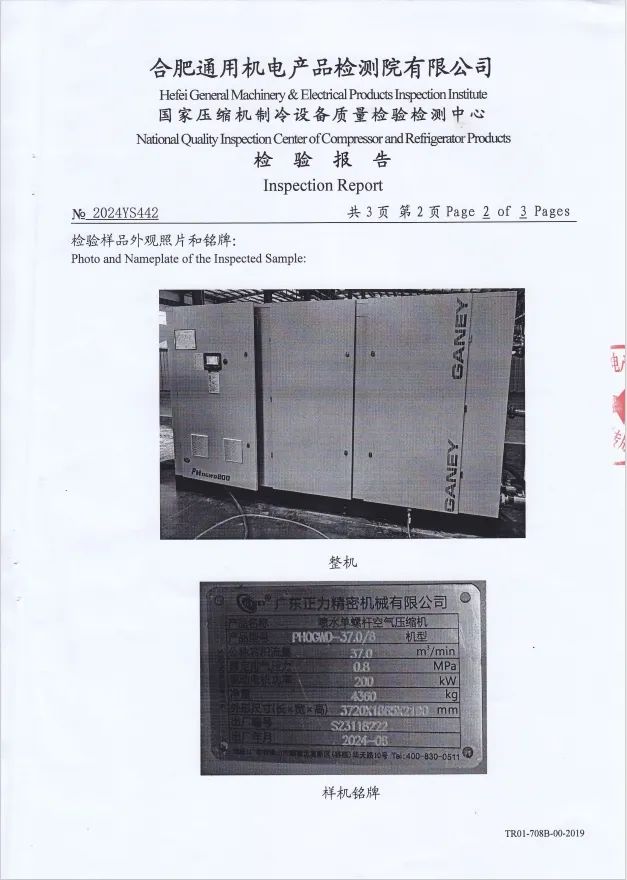

1 Test report – 200kW unit

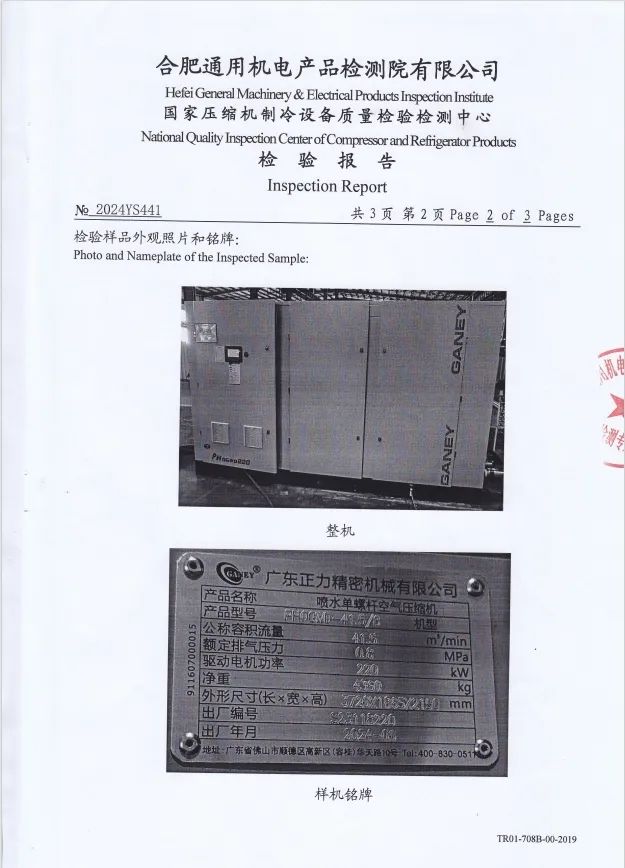

2 Test report – 220kW unit

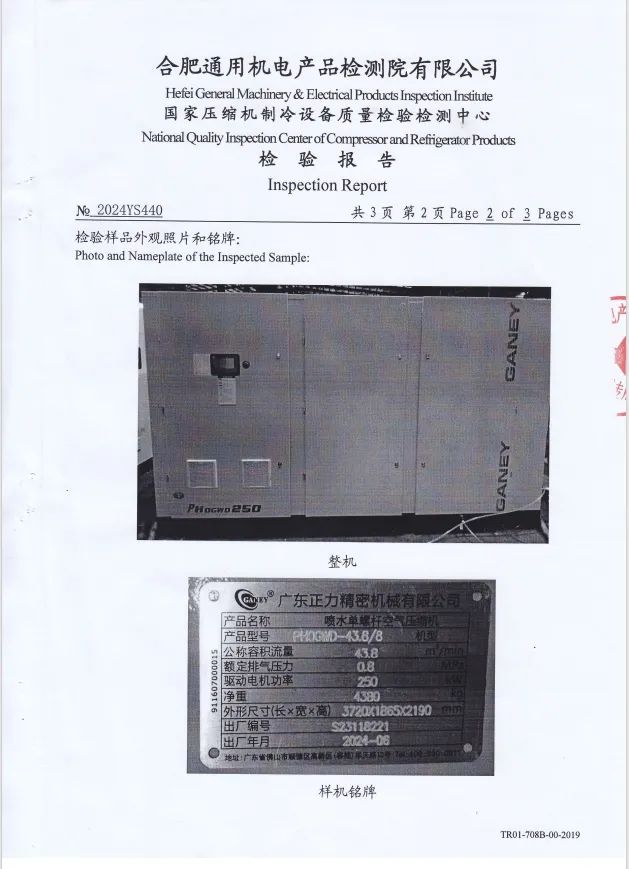

3 Test Report-250kW Unit

2. The first and second stages are connected in series independently, which is convenient for assembly and disassembly and maintenance. The metal parts in contact with water, such as the screw rotor, casing, and machine seal seat, are made of stainless steel, which has excellent rust resistance, is durable, and does not pollute clean air. The three-wire meshing shape independently developed by Zhengli Seiko, the two-stage compression ratio is small and the leakage is small, the water spray seal gap makes the leakage less, and the water spray cooling makes the compression process close to isothermal compression, etc., make the oil-free water spray single screw compressor more efficient and energy-saving.

3. The bearings of each rotor shaft adopt the rolling bearings of the world’s mainstream brand SFK, and the efficient isolation device between the bearing and the machine seal makes the main engine highly reliable, durable and long-lasting.

4. The main system pipeline is also made of stainless steel. From the main engine to the water tank and then to the air supply port, the main pipeline is made of stainless steel, the water tank is made of stainless steel, and the detachable plate is made of stainless steel, which is durable and has a long service life. The use of high-grade stainless steel materials from the main engine to the system prevents the air from being polluted by rust and protects the clean air throughout the whole process.

5. It can be used for industrial frequency and variable frequency. Among them, when the permanent magnet variable frequency drops to the lower limit frequency, that is, the lowest speed, the unit still has less leakage and still has the characteristics of high efficiency and energy saving, making the comprehensive energy efficiency value of permanent magnet variable frequency better.

6. The exhaust temperature of the main engine is low, the operating temperature of the main engine and the parts of the whole system is low, and a low ambient temperature is provided for each component, so that plastic parts, rubber parts, electrical components, etc. work in a good ambient temperature, with high reliability and long service life.

7. Oil-free two-stage water-sprayed single screw air compressor is widely used in various fields such as medical, food and beverage, electronics, automobiles, laboratories, printing, etc. Its low energy consumption, oil-free, clean, safe, reliable, low temperature, no lubricating oil and environmental protection characteristics make it an ideal choice for many key fields.

Some customers’ actual on-site use demonstration of oil-free units

Because there is no oil in the whole machine, the application site is very clean

Post time: Oct-14-2024